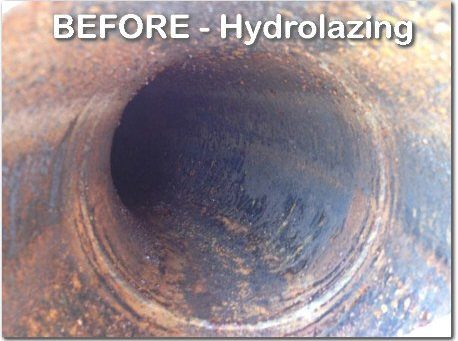

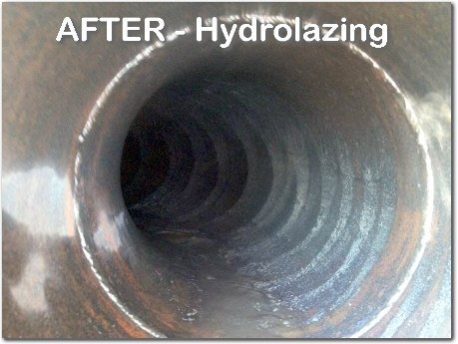

Hydrolazing is also called Aquablasting, Aqualazing, or Hydroblasting. No matter the name the job is done the same way by using a high pressure water jet (15,000 psi to 20,000 psi) to remove mill scale from the internal surfaces of pipe. This process is generally performed on steam piping prior to steam/air blowing of the steam lines to help reduce the time, water, and fuel required to clean the steam piping to an acceptable level required for a turbine manufacturer. Hydrolazing has also been utilized to clean closed cooling water lines, gas lines, and many other lines in the petrochemical, chemical and power industry in a fast and economical method to reduce the amount of waste water generated in the high velocity flushes of those lines. As an added benefit, the water used can be captured and recycled into the Hydrolazing system, conserving this natural resource and limiting waste.

Cogen Cleaning Technology, Inc. has been providing specialty Hydrolazing Services for over a decade. We support the following industry sectors: The Power industry, Pharmaceutical, Refining, Chemical, Pulp & Paper and Manufacturing. The piping systems can be cleaned in up to 1500′ increments, which will minimize the modifications required on the permanent pipe.

The CCT Hydrolazing rotator can accommodate various hose diameters allowing for use of higher pressures and volume to target removal of all types of materials in the pipe. We can adjust the speed of rotation, speed at which it travels into the pipe, and pressure to accommodate the scale in the pipe as some pipes have tougher, thicker scale than others. As an added benefit we offer the use of a borescope to show the client the inside of the pipe once we are finished.

Our Hydrolazing experts have been performing this service since its inception and have experience second to none. Let us show you how Hydrolazing can help save you time and money!